In recent years, different initiatives have been launched with the aim of reducing the environmental impact of the company’s operations, especially in relation to Scope 1 emissions, waste management and water resources.

Grupo Lamosa strictly adheres to environmental legislation in each of the countries where it is present. As of the close of this report, one tile plant in Mexico had Clean Industry certification from the Federal Environmental Protection Agency (PROFEPA) and two plants already had an action plan and were in the midst of the certification process.

Additionally, the company participates in the Green Matters Initiative, with the aim of transforming its manufacturing processes into a low-carbon operating system.

CLIMATE ACTION

GRI 3-3

The company maintains its focus on reducing Scope 1 emissions through energy cogeneration at three tile plants in Mexico, the last one inaugurated in 2016 in the city of Monterrey. These plants run mostly on natural gas, one of the fuels with the least environmental impact.

Moreover, the tile production processes are designed to take advantage of the heat produced both in the kilns and in the atomizer (spray dryer) which is used for the drying process.

Grupo Lamosa is also making efforts to reduce firing temperatures, seeking a substantial reduction in energy consumption. To date, the company has invested more than US$12 million in cogeneration projects.

Additionally, the company’s energy consumption diagnoses have resulted in the replacement of less-efficient lights with much more efficient ones at the production plants.

CIRCULARITY

GRI 303-1, 303-2, 306-1, 306-2, 3-3; SASB RT-CH-140a.3, CG-BF-410a.1, CG-MR-410a.3

Grupo Lamosa responsibly manages the materials and water resources used to make its products. The company operates with the infrastructure necessary to use water correctly, prioritizing its reuse through wastewater treatment plants in 100% of its Mexican tile production centers. For water recycling and discharge, exhaustive quality and safety analyses are carried out.

In addition, efforts are made to recover diverse materials throughout the production cycle, reducing the extraction of virgin materials and their disposal in landfills. Such materials include wood, cardboard, paper, metals and plastics. Assisted by external third parties, Grupo Lamosa facilitates the efficient identification and recovery of materials at its facilities. It is also important to note that all product packaging is mostly made of recycled cardboard.

TILE PRODUCTION PROCESS

GRINDING

Water reuse

ATOMIZING

Energy cogeneration, reduced gas consumption

PRESSING

Recovery of surplus raw materials

DRYING

Recovery of heat generated in firing

ENAMELING

Compliance with regulations for the proper use of materials

FIRING

Redistribution of excess heat generated

SELECTING

Product recovery for grinding

PACKAGING

Use of recycled and recyclable cardboard

ADHESIVES PRODUCTION PROCESS

RECEIVING RAW MATERIALS AND INPUTS

Recovery of materials

MATERIAL DISPENSING

MIXING

BAGGING

Waste recovery

STORING AND DELIVERING

Recovery of materials

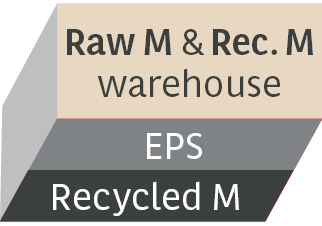

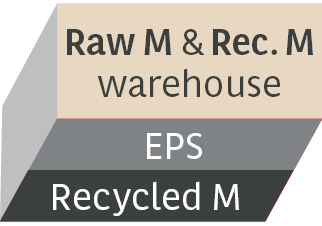

INSULATING AND LIGHTENING MATERIALS PRODUCTION PROCESS

CUT EPS PRODUCTS

MOLDED EPS PRODUCTS

Production and FP warehouse

(20% recycled materials)

![]() Products on sale

Products on sale